Plumbing Architecture – Strategic Design & Product Solutions for Modern Buildings

Plumbing architecture refers to the thoughtful integration of plumbing systems, such as water supply, drainage, venting, and fixture,s within the architectural and structural design of a building.

Rather than being an afterthought, plumbing architecture means routing pipes, manifolds, access panels,a nd fixtures in harmony with the building’s layout, finishes, and long-term maintenance needs. For example, rather than simply dropping a pipe through a ceiling, a plumbing architect will coordinate service shafts, structural beams, acoustic finishess and maintenance access so that plumbing is efficient, accessible,le and discreet.

The discipline covers the full lifecycle: design, installation, and maintenance. A strong plumbing architecture approach ensures compliance with codes that govern plumbing systems in buildings.

When implemented well, plumbing architecture plays an essential role in building performance, occupant comfort, sustainability, and ease of maintenance.

Why the keyword “plumbing architecture” is a transactional-intent keyword

The keyword “plumbing architecture” signals that a reader is likely seeking professional services or specialized products relating to how plumbing is designed and integrated into a building. They may be looking to hire a consultant or source components that relate to architectural plumbing systems.

By targeting this keyword, an article can address actionable solutions such as product selection, service contracts, system upgrades, rate,s and design best practices rather than purely theoretical content. This transactional orientation helps attract readers who are further along the decision-making funnel, making the article more likely to convert leads or product inquiries.

Benefits of adopting a robust plumbing architecture

Enhanced building performance & maintainability

When plumbing systems are built into the architecture from the start, piping, valves, fixtures, and access routes are optimally positioned. This improves flow hydraulics, reduces unnecessary lengths, minimizethe s risk of leakages, and allows easier repairs. Proper design also ensures that drainage slopes, vents,gand traps function correctly.

For example, locating a manifold in an accessible service corridor means less disruption during maintenance. Employing modular valve banks allows isolation of zones during repairs without shutting down entire floors. Over the bubuilding’life span, maintenance costs are lower and downtime is reduced.

Improved occupant comfort, hygiene & sustainability

Good plumbing architecture improves water pressure consistency, optimizes fixture performance, and avoids problems like sewer gas ingress or back-flow. These contribute to occupant health and comfort.

In addition, when plumbing architecture incorporates water-efficient fixtures, greywater recycling, rainwater harvesting, and smart sensors, the building becomes more sustainable ,reducing water consumption, sewage load, and operational cost. This is increasingly important for green building certifications and modern corporate responsibility goals.

Cost savings and smarter lifecycle investment

Designing plumbing architecture early allows designer-engineers to optimizeise riser layouts, reduce pipe material and installation costs, avoid rework during construction, and align service shafts with structural elements.

By selecting higher-quality components upfront, you reduce long-term risk of leaks, failures, and replacements. When plumbing systems are accessible and well-integrated, retrofit costs are also lower when building use changes (for eexamplele conversion of spaces, increased occupancy, or change in fixtures). In short, you invest once for decades of performance.

Technological innovations in plumbing architecture

BIM and integrated service modeling

One of the major advances in plumbing architecture is the use of Building IInformation Modeling(BIM) tools that include Plumbing / Mechanical / Electrical / Plumbing (MEP) coordination. By modeling pipework, valves, fixtures,a nd service corridors within the architectural model, clashes with structure, finishes, or HVAC ducts can be detected early.

This leads to fewer change orders on site and smoother construction. It also produces a digital “as-built” model for facility management, enabling future maintenance or modifications to be better planned.

Smart plumbing components & modular systems

Modern plumbing architecture leverages modular prefabricated piping modules, manifold systems, leak-detection sensors, remote isolation vvalves, and intelligent controls. For example, sensor-based monitoring of water flow can detect micro leaks before they become major issues. Smart valves allow remote shut-off, thereby increasing safety and reducing risk.

These systems support faster installation, high-quality control in factory settings, less on-site labor, and allow buildings to adopt “smart” infrastructure rather than basic conventional plumbing.

Sustainable & high-performance plumbing systems

Plumbing architecture now increasingly includes systems for greywater recycling, rainwater capture, high-efficiency fixtures, dual-pipe systems (potable/ reuse), and advanced drainage systems. These strategies reduce water usage, sewage loadd and contribute to net-zero or green building targets.

Also, material advancements (such as antimicrobial piping, corrosion-resistant alloys) protect against failure and prolong the service life of plumbing systems.

Five real-world products relevant to plumbing architecture

Here are five specific products that can play important roles in plumbing architecture projects. For each, I provide detailed information, use-case/example problems they solve, need to use them, and how/where to buy.

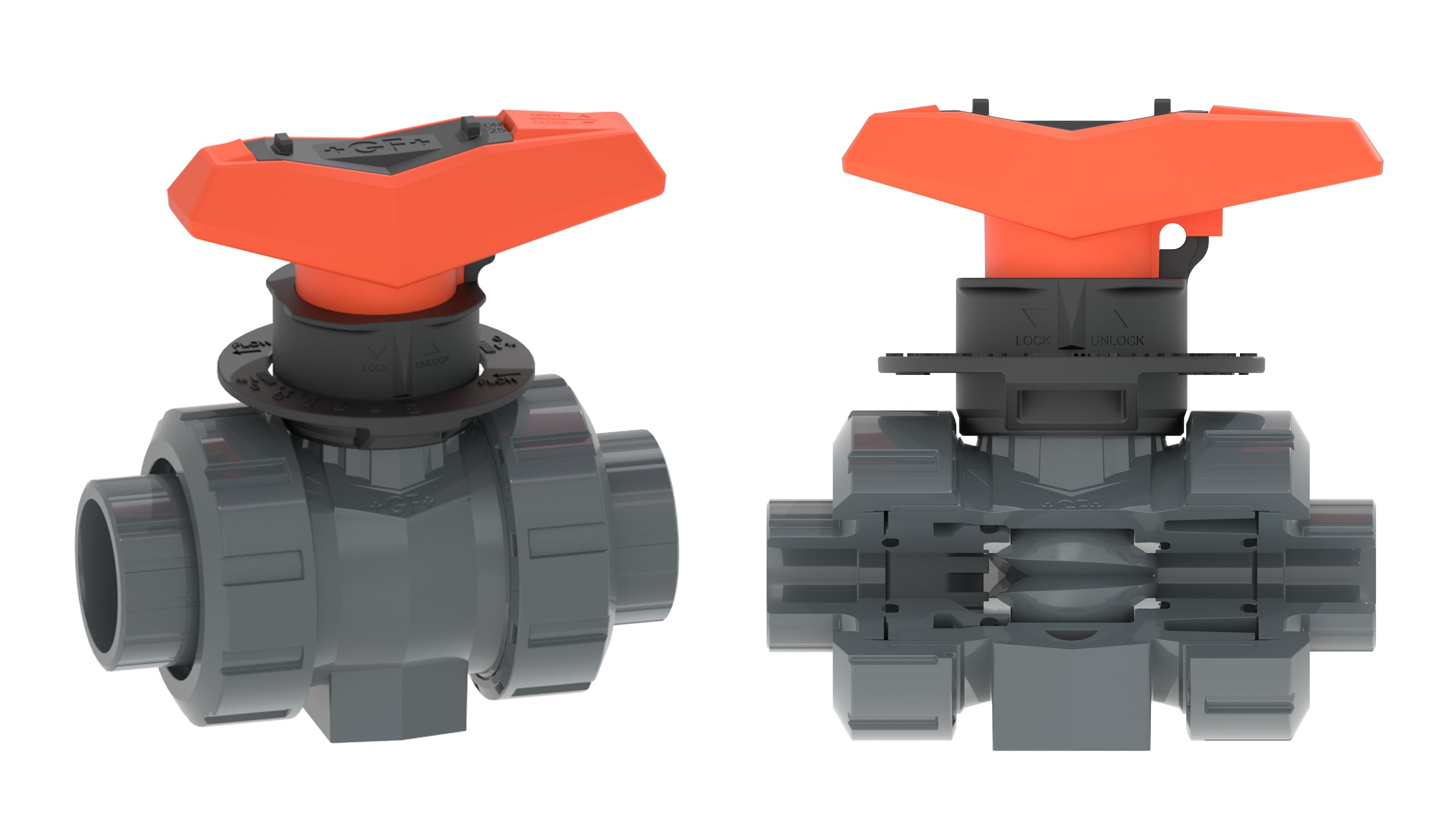

GF PIPING SYSTEMS Manual Ball Valve 167546333

Detailed information: This is a full-poly union manual ball valve from GF PIPING SYSTEMS, model 167546333, for ¾″ pipe. Ball valves are used to shut off water flow completely and rapidly, and the union (disconnect) allows servicing without removing entire pipe sections.

Use-case/pproblemsolved: In a building plumbing architecture design, you may need to isolate entire plumbing zones (for maintenance, emergency repair, or tenant turnover) without shutdown of other areas. A reliable ball valve in the riser or manifold allows that. Without it, you’d have to shut down a bigger area, causing disruption.

Why people need it: Because modern buildings expect minimal downtime, equipment failure,s r maintenance interruptions. Using a quality shut-off valve such as this improves serviceability and redreduces thesk of water damage or business interruption.

How to buy / where to buy: Available from industrial plumbing suppliers or specialist online distributors.

Flow Control Motorized Electrical Ball Valve DN50 2″

Detailed information: This is a motorized electrical ball valve (DN50 / 2″) which can be controlled remotely or automatically (220 V 2-way). Motorized valves are part of “smart” plumbing architecture where remote control or automated shut-off is needed.

Use-case/problem solved: In a large commercial plumbing architecture design, you may want remote isolation of certain zones (floor, tenant, lab, server room) in case of leak detection, fire sprinkler shut-offf or operational control. A motorized valve offers that. Without it, manual intervention would be required, delaying the response.

Why people need it: It enhances building automation, reduces downtime, allows integration with building management systems, and supports faster responses to leak or fault detection. This adds value to plumbing architecture by improving responsiveness and reducing risk.

How to buy / where to buy: Available through online marketplaces and dedicated valve supply networks.

Legend 3/4″ MPT × 3/4″ D Pack Joint Bronze Coupling

Detailed information: This is a bronze coupling fitting rated for ¾″ threads (male pipe thread to female or D-Pack joint). Couplings and adapters are vital for plumbing architecture because they connect different pipe types, sizes, or system materials.

Use-case/problem solved: In a complex plumbing architecture scenario, you might be transitioning between new materials (e.g., PEX to copper) or you may have retrofit work in an existing building. Having quality coupling ensures leak-free joints and compatibility. Without proper fitting,syou risk corrosion, leleakss and future failures.

Why people need it: Because plumbing architecture depends on reliable connections, materials compatibility, and serviceability. High-quality fittings deliver durability and reduce maintenance costs.

How to buy / where to buy: Sourced via industrial supply houses or global online retailers.

GF PIPING SYSTEMS Check Valve 192304010

Detailed information: This is a check valve model 192304010 by GF PIPING SYSTEMS, designed for single‐flow applications (1½″). Check valves allow fluid flow in one direction and prevent backflow. They are crucial in plumbing architecture for drainage, supply recirculation,a nd safety.

Use-case/problem solved: In plumbing architecture, preventing back-flow is essential to avoid contamination, reverse flow in supply lines, or overflow in drainage. A check valve ensures correct flow direction without relying on manual intervention. Without it, you risk contamination, floodingg or system malfunction.

Why people need it: Because building a plumbing system requires safety compliance, consistent operation, and prevention of system failures. Quality check valves are part of that assurance.

How to buy / where to buy: From specialist plumbing or industrial suppliers.

HFS 3/8″ NPT Female Thread Pipe Fitting 4-Way Stainless Steel

Detailed information: This is a 4-way stainless steel pipe fitting with female NPT threads, 3/8″ size. Stainless fittings are used in specialized plumbing architecture zones (laboratories, medical facilities, high-corrosion areas) where durability and hygiene matter.

Use-case/problem solved: In buildings with specialized plumbing architecture (medical, lab, food processing, high-humidity zones), standard fittings may corrode or fail prematurely. A stainless steel 4-way fitting allows branching of multiple services and a durable connection. Without such premium fitting, you risk frequent replacement, maintenance headaches, and system downtime.

Why people need it: Because advanced building typologies require plumbing architecture that is robust, hhygienic and long-lasting. Premium materials play a role in that assurance.

How to buy / where to buy: Available via online sales or stainless-steel fittings specialists.

How these products enhance plumbing architecture

Integrating these products within the building design and construction process enables plumbing architecture to deliver on its promises. For example:

- UUsing motorizedvalves allows integration with building automation and rapid isolation of zones during leaks or maintenance.

- High-quality ball valves placed in key risers ensure minimal disruption when servicing the system.

- Premium fittings and couplings ensure longevity, ease of service, and compatibility with new materials or retrofit zones.

- Check valves safeguard against reverse flow and contamination, enhancing system reliability and occupant safety.

- Premium stainless-steel fittings allow specialized zones (labs, food, medical) to have robust plumbing architecture.

Together, these products support objectives including serviceability (easy access, isolation), longevity (durable materials), performance (hydraulics, flow), and flexibility (modular, future-proof).

How to buy and where to purchase for plumbing architecture applications

When buying components for plumbing architecture, follow these steps:

- Define specifications: Determine material (copper, PEX, stainless, PVC), pipe size, pressure rating, thread standards, certification, and application (potable, wastewater, recirculation).

- Select suppliers: Choose vvendors specializingin commercial or industrial plumbing supplies rather than basic retail-only.

- Quality vs cost: Higher-quality materials and trusted brands reduce long-term risk of failure, downtime, and maintenance costs.

- Compatibility and integration: Ensure products are compatible with the plumbing architecture design and that contractors are familiar with the brand or type.

- Procurement timing: Order early to avoid delays.

- Installation and documentation: Ensure installers are certified, follow manufacturer instructions, and keep documentation as partof the building handover.

Implementation steps for plumbing architecture in building projects

- Early coordination: Engage plumbing engineer, architect,a nd MEP team during schematic design.

- Material and component selection: Choose high-quality valves, fittings, sensors, and piping systems.

- Modeling and clash detection: Use BIM/MEP tools to model plumbing systems and detect conflicts early.

- Detailed design & documentation: Develop plumbing drawings, valve schedules, and installation sequences.

- Procurement & logistics: Ensure compliance with local standards and account for delivery lead-time.

- Installation, commissioning & testing: Validate flow rates, pressure test systems, and document commissioning results.

- Hand-over & maintenance planning: Provide as-built drawings, manuals, aand spare partslists.

- Post-occupancy review: Monitor water usage, leak detection, and performance.

Why you should prioritize plumbing architecture now

Modern buildings face higher performance demands: occupant comfort, sustainability, adaptability, minimal disruption, and long-term value. Plumbing architecture addresses these by embedding plumbing systems not as retrofit add-ons, but as integral elements of building design.

Investing in plumbing architecture delivers: fewer maintenance interruptions, better occupant health, lower lifecycle cost, and improved asset value. The right choice of components paired with early coordination and smart installation transforms plumbing from a hidden cost center into a well-managed service.

FAQ

Q1: What distinguishes “plumbing architecture” from standard plumbing installation?

Answer: Standard plumbing installation typically involves connecting fixtures, pipes, and drainage without significant integration into the architecture or future servicing strategy. Plumbing architecture, however, involves planning plumbing systems as part of the overall building design—coordinated with structure, finishes, service access, maintenance strategyy and building lifecycle concerns.

Q2: At what stage should plumbing architecture be designed in a project?

Answer: The plumbing architecture design should begin at the early design stage when the building layout, structural grid, service shaft ,,ts and zones are being defined. Early coordination prevents clashes, ensures efficient pipe routing, defines maintenanaccessacc,s and allows optimal component selection.

Q3: How do I choose components for plumbing architecture vs standard components?

Answer: When choosing components for plumbing architect, you prioritize: compliance with local codes, high durability materials, ease of maintenance, integration with building automation, compatibility with system layout, and lifecycle cost.